3D Design & Fabrication

3-Day Design Proposal: Building Facade

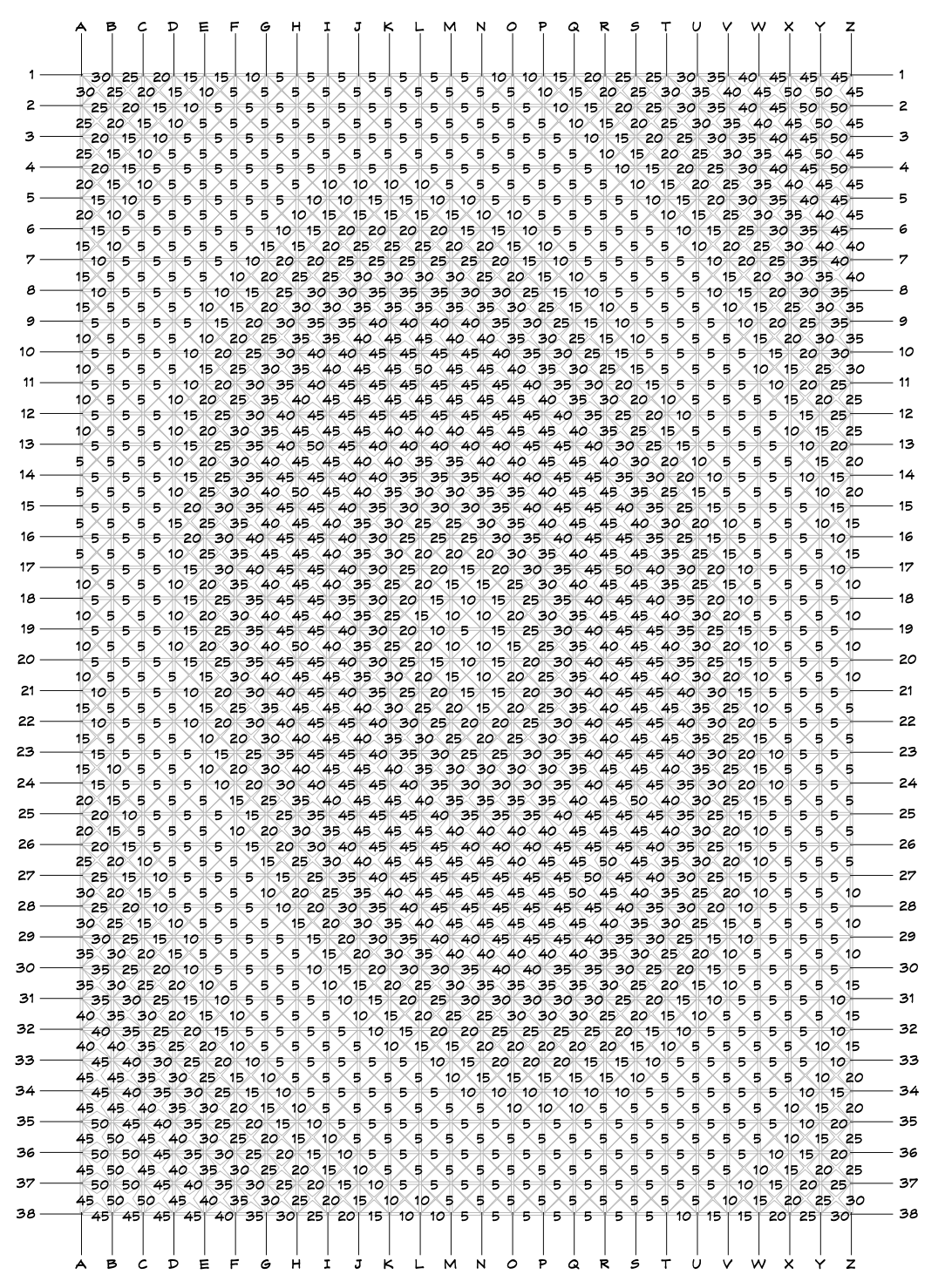

Bent Steel Panels on Steel Grid

This is a quick and dirty project to demonstrate a concept. We would bend steel panels and attach them to a 2” square tube steel grid to produce a halftone effect on the entire side of a building.

To expedite the design of this project I wrote a custom plugin to quickly visualize the final result and generate some of the supporting documents.

Three views of the proposed design

A few of the design documents. The bill of materials and the installation chart are generated by my plugin.

SketchUp plugin code

Custom SketchUp plugin in action. It uses an image to set the bend angles on any number of individual panels.

Quick renderings of alternate designs. (Click to enlarge.)

Summary

By the time this proposal is presented, there are numerous options to choose from and an infrastructure that would allow us to quickly visualize new ideas.

Hyperbolic Roof: 1-Day Feasibility Study

CNC-Carved Plywood

3-Point Hyperbolic Roof

Two Problems

Plywood isn’t long enough to make the ribs in one piece.

Because of the curves, making ribs that use the full length of the plywood is wasteful. When I cut the ribs to 8’ lengths, many plywood sheets can only fit one of them.

A Solution

Make two copies of each piece from 1/2” plywood, then glue them together to make 1” thick ribs.

Create enough overlap to be strong.

Split them on slot lines so the cuts are hidden when the piece is assembled.

Part Organization

Another challenge was to avoid creating a giant jigsaw puzzle. These shapes are very similar, easy to confuse, and the sheets are laid out to optimize the material - not to keep the parts organized. An easy solution is to include part numbers in the cut plan and run a quick pass to carve them into the parts before cutting. (Notice, again, that the numbers are placed so that they will be hidden when it is assembled.)

Summary

At the end of this study we know how much material will be required, we have approximate cutting times, and can create a realistic proposal for this part of the design.

SOFTIES: 1-Day Design

CNC-Carved Foam - 3D Storefront Sign

Use digital sculpting tools to design the 3D shapes.

Use the 3D shapes to generate the shapes of the foam slices.

Optimize the arrangement of the slices to minimize material use.

Here is one of the CNC cutting paths, including little tabs to keep free parts attached to the sheet. This allows us to pick up the whole sheet at once and place the next one to minimize machine time.