Printing 1,000 Business Cards

A few folks have asked me how I print 1,000 business cards. One at a time? In big sheets?

For now, I am printing them one at a time on a giant press powered by a foot treadle. Eventually, I might be busy enough that I can set up the press to print two or four jobs at the same time. They would, of course, need to use the same paper and the same ink.

Before the printing I cut down big sheets of paper into business card size. In the following time-lapse video, you can watch me start with 11 sheets of paper – 10 for the main job and 1 for proofing a job that’s being designed right now – and use the giant manual guillotine to cut them down. I do it this way rather than to buy pre-cut cards because I want to offer the most number of paper options that I can and keep the prices reasonable.

The process takes about 45 minutes for one batch of cards, but I’ve compressed it to less than 45 seconds for your enjoyment.

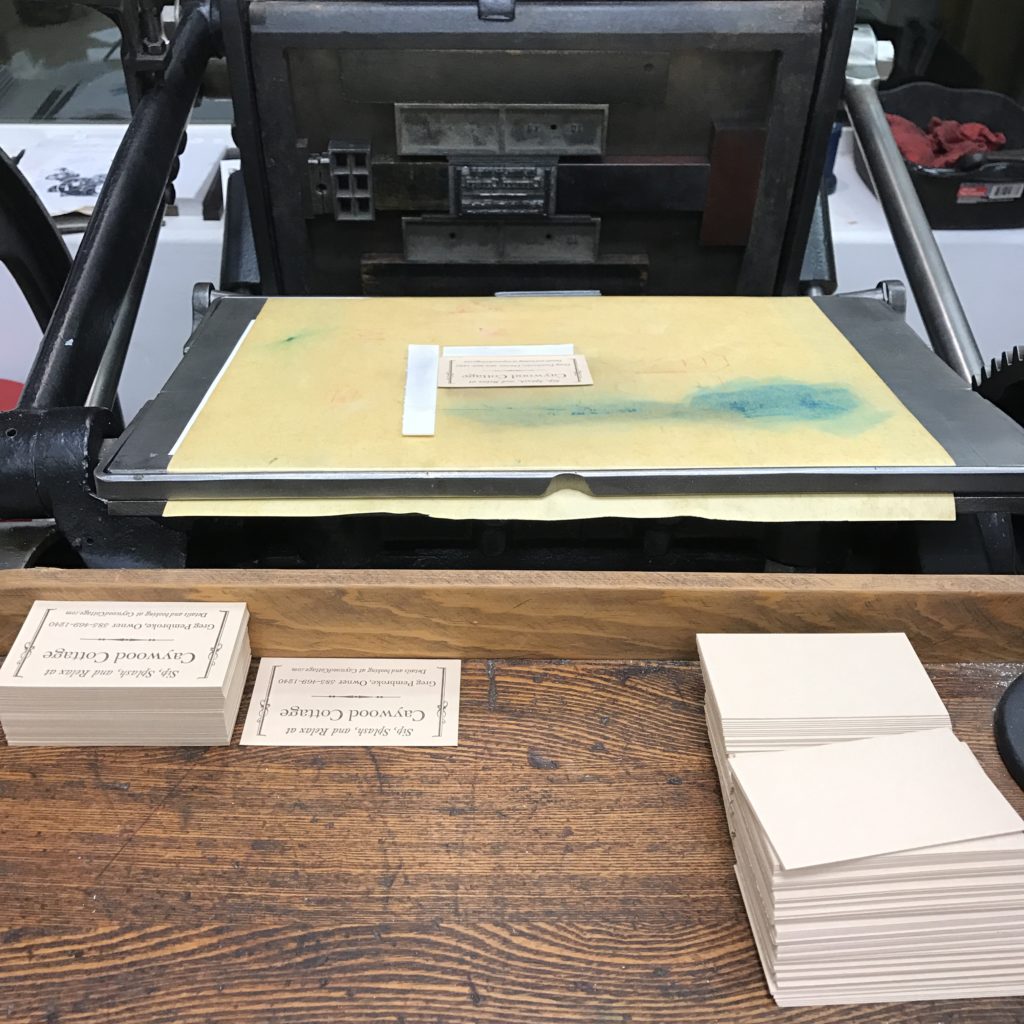

When the cutting is complete, I have stacks of blank cards ready to print. They go to the feed board, always at hand while printing. This board can swivel to move them further and closer, depending on the type of job and how much space I need to move into and out of the press.

Here’s an overview of the press and delivery board. While the press opens and closes, the right hand puts blank cards onto the registration tabs as the left hand removes the printed cards and puts them on the “finished” stack.

[The Workstation]

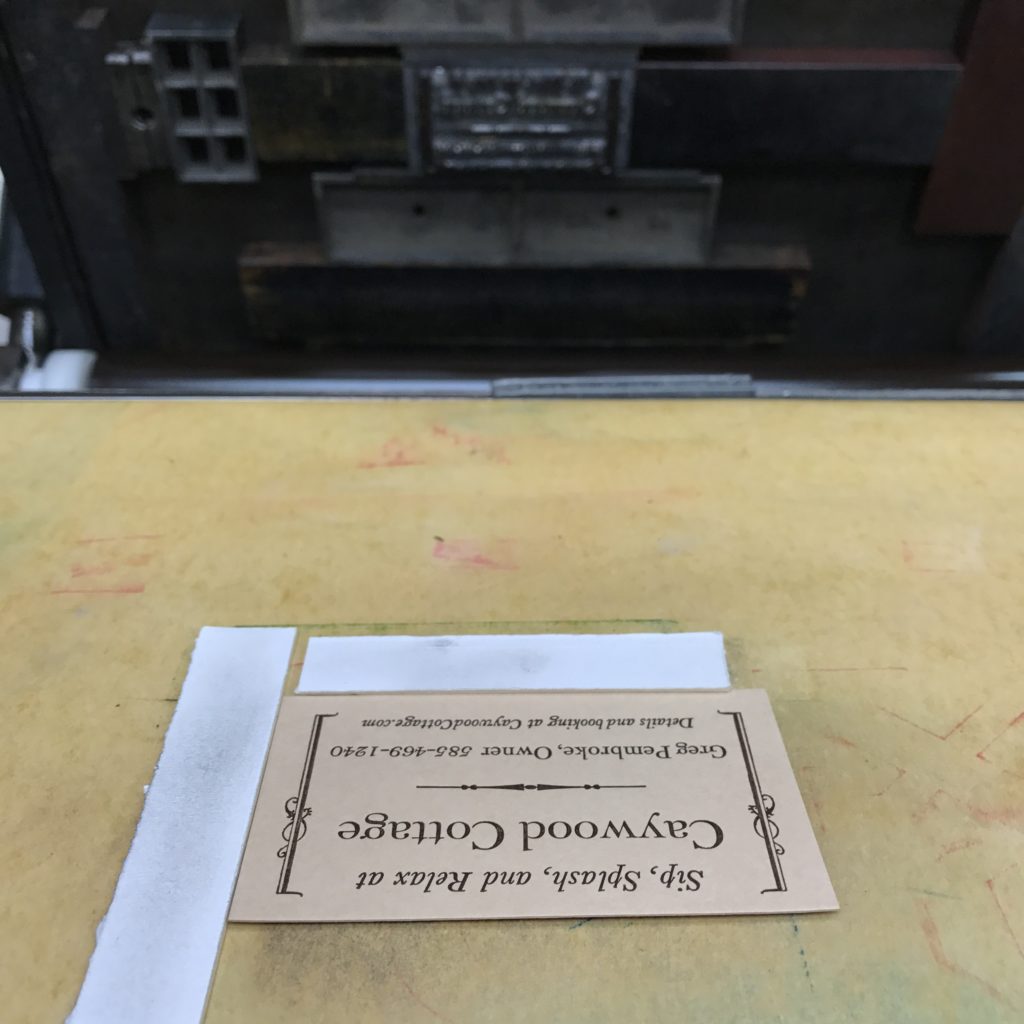

Sometimes, some of the letters will stop printing. This is very old type and has seen decades of use in who-knows-how-many print shops. A few of the letters are already mashed down (by 0.0001″ or so) and don’t always pick up the ink in the same way as the others. These need to be replaced on the fly. By keeping the standard on the board, my eyes can spot tiny differences quickly without stopping to inspect every card.

[Ink Standard]

[Fanned Blanks]

[Finished Job]

If you want me to design and print you some business cards, use the contact form HERE to send me a message. I’ll help you through the process of designing your card and picking the paper and ink to get you just the look you want.

(And, Greg, thanks for letting me use the pictures of your job to tell this story.)

Sorry, the comment form is closed at this time.