January 31, 2016

In

Uncategorized

Jig Trouble

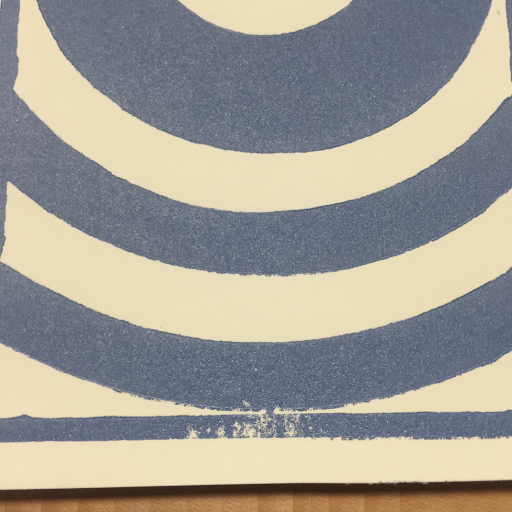

Beginner’s luck, that’s what I’m calling my last month of success with the registration jig. I’ve pulled hundreds of impressions with fantastic registration and no problems.

[Jig and print]

Well, that run came to an end today. I decided to try cranking up the press tension 1/4 of a millimeter. On the first print with the new setting, one of the registration pegs sheared off.

“Huh. Must have been a weak spot in the wood,” I thought to myself. Uh, nope! The next impression sheared off another peg. Then another and another.

[Last print with two sheared pegs stuck in the paper.]

Ah, well! This is why I use the CNC cutter, right? I can just make a new one. Well, yeah, I can. But maybe I should have had more coffee first. I was apparently asleep at the wheel.

[Ink missed the paper]

See those skipped spots on the print? It must have been badly inked, right?

[Ink still on the block]

Well, no. The ink is still sitting there on the block. What!? Why?

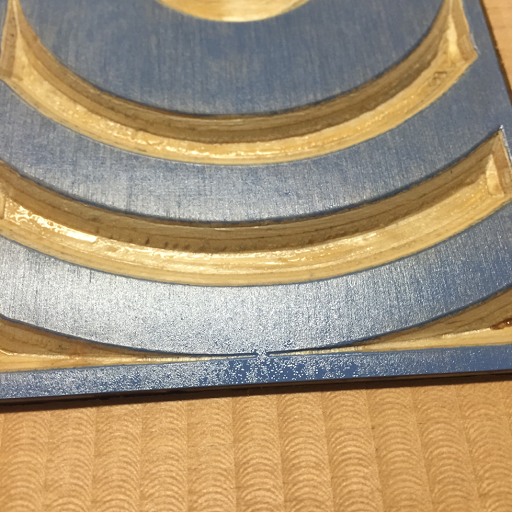

[Hanger slot from when this piece of wood was going to be a sign]

Oh, look at that! There’s a bit of support structure that’s missing from the jig. It didn’t seem like a big deal when I carved it. I mean, the block is 1/2″ thick birch. It wouldn’t flex so much over such a short distance that it totally misses the paper, would it?

Well, yes, it would. Back to the wood shop. This time I’ll pay closer attention.

Sorry, the comment form is closed at this time.