December 23, 2015

In

Uncategorized

Registration Jig Results

This is a continuation of yesterday’s post about building a jig to test a type of registration where the paper is lined up in one corner and the block is lined up in the opposite corner.

[block and paper in the jig]

I found some pretty serious requirements of this system. First, the blocks must be perfectly square. Mine are square on two corners while the other two are off. (I used the wrong tool to cut them.) Second, the paper also needs to be square. Third, the paper needs to be laid down exactly the same way each time. The change in height between the block and the bottom edge of the paper adds a significant amount of play in the vertical aspect of the registration.

Those things said, here are the actual results from the test…

[unsquare block corners and unsquare paper]

[two passes laid down differently, probably because of height difference]

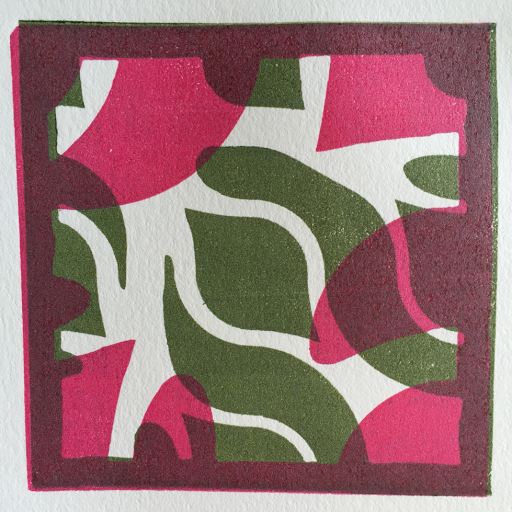

I have a lot to learn about the theory and the reality of ink viscosity. The following image doesn’t show it very well, but the third pass with the green ink pulled up the wet ink from previous passes instead of covering it with green. I think that the green was more viscous and that it pulled up areas of the less viscous cyan and magenta.

After I learn the theory, I then need to learn how to mix inks of differing viscosities and how to determine the viscosity of a pool of ink on the slab.

[something funny happened with the ink]

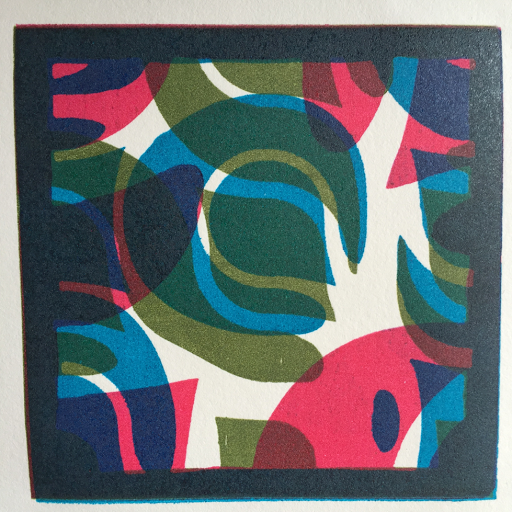

[again, the height difference led to bad vertical registration]

This last image was the most successful, but sort of a fluke since the height of the block really throws a spanner into the works of vertical registration. The next system that I try will need to lift the paper up to the height of the surface of the printing block.

Sorry, the comment form is closed at this time.